43 how to label racks in a warehouse

Warehouse Labelling 101 - Best Warehouse Labels And Labelling Ideas How To Label Warehouse Racks Properly Here is are some useful tips on how to label your warehouse rack like a pro: Type of rack shelf: You must identify the warehouse rack you have as racks are available in different options. Select the type of rack you want depending on the storage demands of your product, then choose the appropriate labels. Warehouse Racking: The Ultimate Guide - Conger Industries Inc. Density refers to how much product or material is stored in a warehouse. Different types of warehouse racking will allow you to store more material (i.e. higher density) or less material (i.e. lower density). High-density racking systems include: Double or triple depth racks. Drive-in/drive-through. Push back.

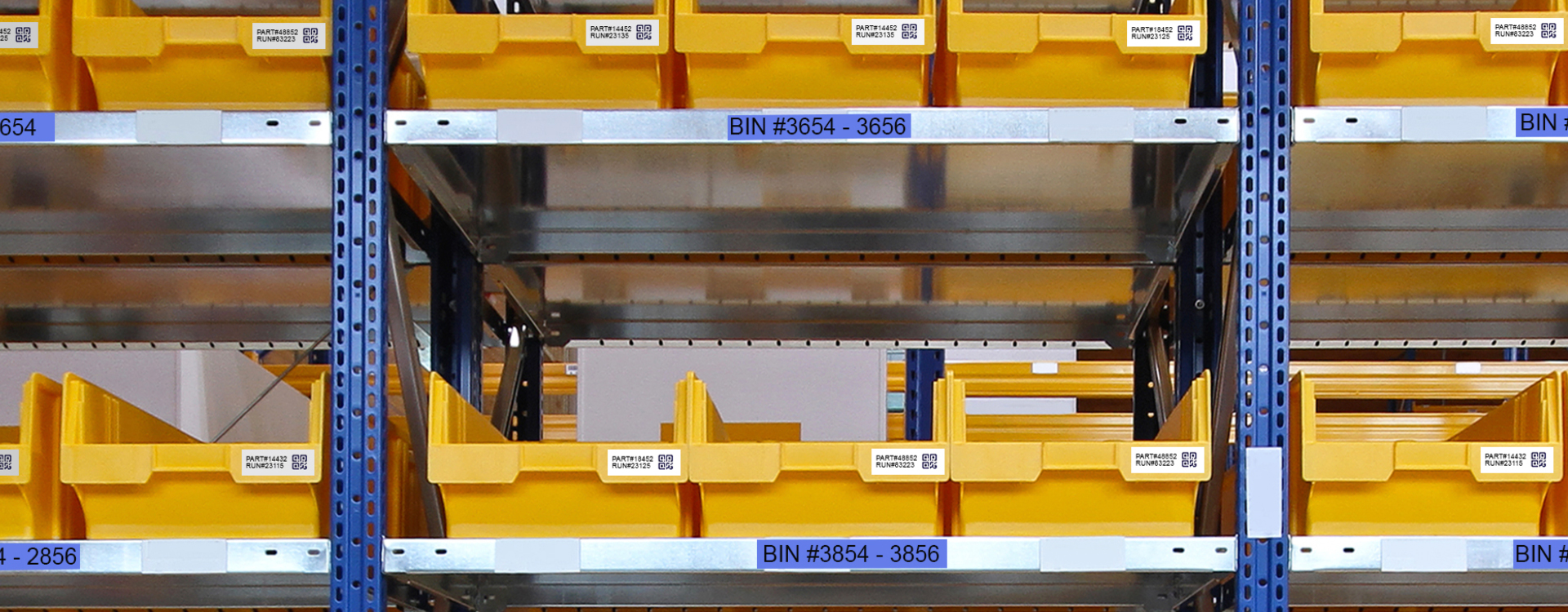

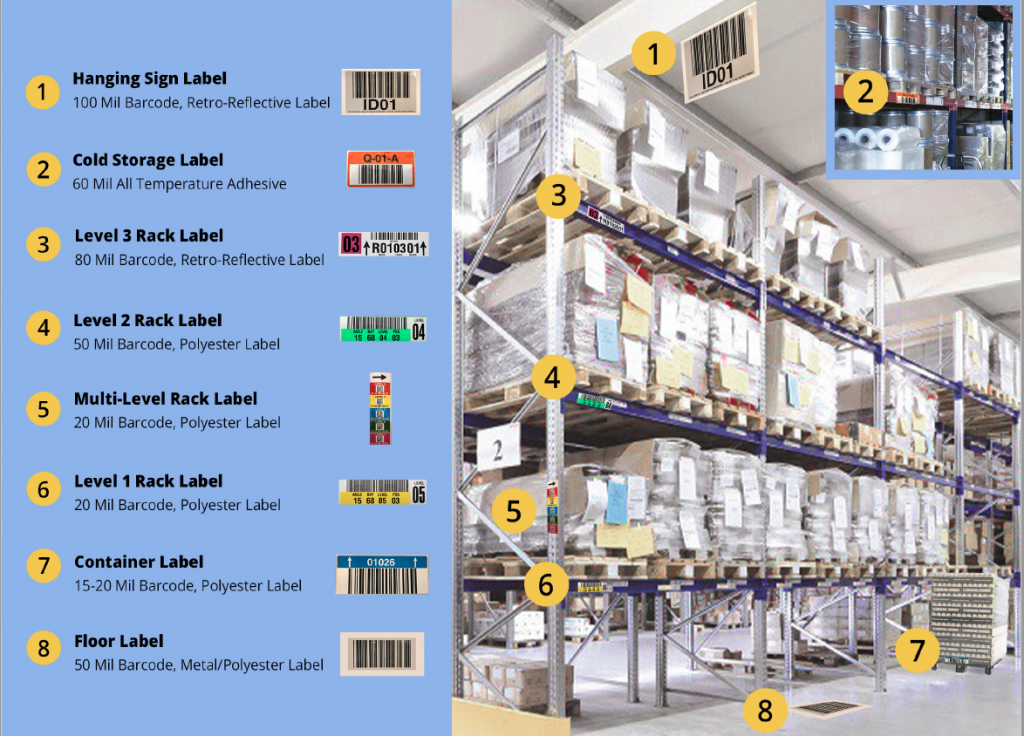

Warehouse Rack and Bin Location Labels | ID Label Inc. Rack, Shelf and Bin Location Labels. Warehouse location labels help to efficiently track and identify products for storage, picking and inventory management. They typically include a one- or two-dimensional barcode image and human-readable letters and numbers. Color coding is another common feature to help workers quickly identify the correct ...

How to label racks in a warehouse

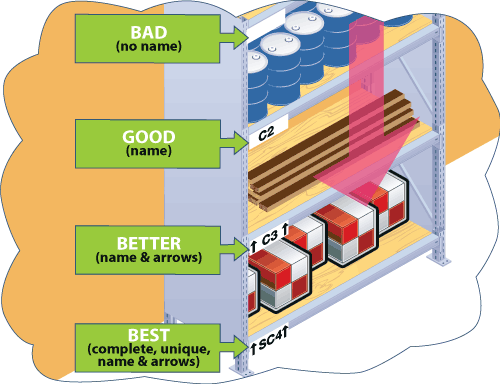

Warehouse Racks Labeling Guide & Idea - SPS Ideal Solutions Ensure that the Racks are ready to Label: Sticking labels on a dusty surface is not advisable as it creates performance and durability issues. Hence, prior to the labeling the rack, ensure to clean the surface in order to enhance the label's adhesive value. Also, ensure that the information printed on the label goes in hand with the stored items. Quick Tips for Warehouse Rack Labeling Systems Safety Labels Sign Posts Browse All Facility Safety Floor Signs Safety and Caution Signs Caution Icy Surface Floor Sign Caution-Keep Clear Of Moving Parts Floor Sign Please Keep Your Distance Floor Sign Traffic Floor Signs 3-Way Intersection Floor Sign 4-Way Intersection Floor Sign Authorized Personnel Only Floor Sign Pedestrian Walkway Floor Sign Warehouse Rack Labeling Best Practices - BarcodeFactory Blog Warehouse Rack Labeling Best Practices. Feb 4. Highlighting the identification of racks, isles, and sections of a warehouse improves employee productivity. Even with the most elaborate digital tracking system, nothing is faster or easier than looking at a clearly marked label. When that label is equipped with a scannable barcode you have a ...

How to label racks in a warehouse. Naming and labelling warehouse bins and shelves - Datalinx Blog Then the bin 'mapping' requires further examination and coding. Perhaps for 'aisle' positions in the shop and warehouse areas. Note: an aisle may be the 'work space' between two separate racks, etc. Ends of aisles should be clearly labelled. The example (Fig 1) below shows two racks along the outer walls and three back to back racks. How to Label a Warehouse - Express Corp Removable Labels: For warehouses that regularly carry out reconfigurations, removable label racks make it easy for relabeling rack locations. They are simple to install, and as with other label options, they can be designed in different sizes. Permanent adhesive: Most permanent adhesive labels are applied on materials that require a one-time label. Warehouse Locations and Bin Labeling: Best Practices and Tips - SkuVault Racks (AKA units or section) can be thought of as large sections of shelving units that store your product. Depending on the warehouse, racks/units might be identified as an entire shelving unit spanning one side of an aisle or as small sections within a long until of shelving. Tips for Effective Warehouse Numbering Schemes - ID Label Inc. For instance, vertical location labels, also known as totem labels, are an excellent solution for multilevel warehouse racks. These labels mark each rack bay location and are used to identify products for storing, picking and inventory management. If you need to be able to scan the top levels from the ground, totem labels eliminate the need for ...

Best Practices for Warehouse Labeling - Supply Chain & Logistics Basics First, identifying the barcode scheme that works for all parties involved is standard - both the GS1 and UPC schemas are used frequently. Between your partners, identify what inventory data must be readable within this schema (i.e. expiration date, manufacture date, weight, serial). Next, consider what label material will be best for your ... How To Make Good Labels For Inventory Locations First, position yourself in the first area/room/zone that you want to start labeling, and stand in front of where you want to start your sections. Then write or create your label. Remember, you want to include the FULL LOCATION name on the label. (If you're using the paper strips, pen, and tape, write the location name on the paper strip ... Warehouse Rack Labeling Ideas: Keep An Organized Warehouse When labeling your warehouse racks, you have two main options: the serpentine method or the standard method. Each has its own benefits and drawbacks, so it's essential to choose the right one for your needs. Serpentine method - The serpentine method is the most efficient way to label racks. How To Label Warehouse Racking - inotec How to label warehouse racking In order to label warehouse racking efficiently and accurately, inotec UK has established a process which simplifies the development and installation of warehouse labels. To be able to fully understand your warehouse, inotec take the time to visit your site, observe processes and speak to personnel.

5 Keys to Warehouse Rack Labeling | Express 1) Identify racks - As an example, consider the many ways that sections or units of shelving can be positioned to hold gear. There might be a single, elongated unit or many smaller, single units. It often depends on issues like product size, the numbers of SKUs at work, the variations in products, and more. What Are The Ways to Label Bin and Rack Locations? | SOLUM Having a proper bin and rack labeling system will prove to deliver big payoffs in terms of ease in warehouse management and efficiency in logistics operations. For many people, the labels they see in racks and bins inside warehouses and stores may seem like a minor or not-so-important detail. 4 Proven Options for Relabeling Warehouse Racks - ID Label Inc. Nov 8, 2018 ... 2. Magnetic Warehouse Location Labels ... Labels adhered to magnets are another viable option to consider, whether for rack beams or vertical ... Pallet Rack Capacity Labels & Their Importance - SRS-I A typical label should feature the following: Aisle numbering or equivalent identifying code. Minimum area 50 square inches (e.g., 10" x 5"). Clear, legible print (e.g., white or yellow background, standard sans serif font, black text). Maximum permissible load for each pallet or unit OR maximum uniformly distributed load per level.

Warehouse Labeling Ideas: Warehouse Rack Labels and Labeling - BlueCart Since racks are the least likely type of shelving to be moved, applying warehouse rack labels should be done as soon as possible. There are two common approaches for warehouse rack labeling ideas: standard labeling and serpentine labeling. In standard rack labeling, products are labeled in parallel structure.

What are the best way to label warehouse racks? - Creative Safety Supply Some of the best ways to label racks in warehouses involve: Utilizing a sequential system - This is an important aspect of using location labels for racks and other storage spaces because it will help the employee ultimately find a product. This is why alphanumeric systems work so well rather than the use of colors which don't have a clear order.

Rack Labeling | Creative Safety Supply Warehouses typically will use 1D barcodes; 2D barcodes are more common for instances where people may use their cellphone to scan tickets or make a purchase. Other Rack Labeling Materials In addition to barcodes made with traditional vinyl, there are other kinds of supplies that help you organize your racks, such as: Magnetic Labels.

New Warehouse Design? Tips on How to Label Warehouse Racking - LIDD Within each rack bay, each position can be numbered. For pallet slots, this means 2 positions per rack bay but it can increase as needed for handstacks. For example, rack bay 21 with two pallet positions could be 21-1 and 21-2 and rack bay 22 with 6 handstack positions can be 22-1, 22-2, 22-3, 22-4, 22-5, 22-6.

A Guide to Labelling Warehouse Racks - rslni.com The first step to effective warehouse labelling is an identification system. Once all of your stock and equipment has been organised and put into its rightful place, code labels can be used to identify items clearly in order to minimise time loss and costly errors to your business.

Warehouse Rack Labeling PaladinID - YouTube Need to label your warehouse, but don't know where to start? You have come to the right place. PaladinID can take your concept to finished product and even...

How To Label Your Warehouse Bin Locations - YouTube Feb 18, 2021 ... Most warehouses have a structure in place with different areas, racks, bays, levels, and pallet positions. To organize this structure in a ...

How To Optimize Warehouse Efficiency With Right Labeling Methods Jul 1, 2019 ... Labels should use a combination of numbers and letters in sequential order to identify the exact location on the rack. It wouldn't make sense to ...

How to Label Shelves in a Warehouse - Oakway Storage Limited Warehouse labelling is one of the most important aspects of efficient warehouse management. Labelling can refer to identifying products within a storage facility so that they can be easily stacked and found again, or for other warehouse equipment such as pallet racking, shelving systems, aisles and loading areas.

How to Label your Warehouse, Tools and Assets WITH EASE! How to Label your Warehouse, Tools and Assets WITH EASE! - YouTube How to Label your Warehouse, Tools and Assets WITH EASE! Neumann Marking Solutions 1.63K subscribers Subscribe 62 12K...

Warehouse Rack Labels and Inventory Labeling Solutions - Camcode By considering your inventory system, scanner type, scanning distance and angle, and mounting method, we assure that you receive the highest value warehouse rack labeling solution. 2:32 Better Inventory Control and Data Management with Camcode's Warehouse Rack Labeling Solutions

Top Warehouse Rack Labeling Ideas to Boost Efficiency How to label racks in a warehouse? Here's how to do it systematically. Bottom-Up Rack Labeling System Choose Between a Serpentine or Standard Method Choose the Best Warehouse Labeling Supplies 1. Rearranging Inventory Regardless of the warehouse layout, you need to plan the contents of your racks and shelves systematically.

What is the Best Way to Label Bin and Rack Locations? - YouTube Aug 9, 2021 ... Bins and racks provide great help to identify where products are located. It accelerates your warehouse's overall operations.

How to Label a Warehouse Rack - Camcode Let's take a look: Identify Your Racks No matter what your organizational scheme may be in regards to your warehouse, the very first step in proper labeling is a simple one - identifying your racks. It may seem like a common-sense move, but not every operation follows the same definition.

Warehouse Rack Labeling Best Practices - BarcodeFactory Blog Warehouse Rack Labeling Best Practices. Feb 4. Highlighting the identification of racks, isles, and sections of a warehouse improves employee productivity. Even with the most elaborate digital tracking system, nothing is faster or easier than looking at a clearly marked label. When that label is equipped with a scannable barcode you have a ...

Quick Tips for Warehouse Rack Labeling Systems Safety Labels Sign Posts Browse All Facility Safety Floor Signs Safety and Caution Signs Caution Icy Surface Floor Sign Caution-Keep Clear Of Moving Parts Floor Sign Please Keep Your Distance Floor Sign Traffic Floor Signs 3-Way Intersection Floor Sign 4-Way Intersection Floor Sign Authorized Personnel Only Floor Sign Pedestrian Walkway Floor Sign

Warehouse Racks Labeling Guide & Idea - SPS Ideal Solutions Ensure that the Racks are ready to Label: Sticking labels on a dusty surface is not advisable as it creates performance and durability issues. Hence, prior to the labeling the rack, ensure to clean the surface in order to enhance the label's adhesive value. Also, ensure that the information printed on the label goes in hand with the stored items.

Post a Comment for "43 how to label racks in a warehouse"